Connected Assembly: How AR Enhances Productivity and First-Time Accuracy in Manufacturing

As factories race toward Industry 4.0 transformation, the assembly line is becoming smarter, faster, and more interconnected. But even with high-tech machines and automation, one area remains prone to bottlenecks and errors: manual assembly tasks.

That’s where Fekki.io’s AR-powered manuals come in—bridging the gap between human workers and digital precision to create what we call Connected Assembly.

The Assembly Line Challenge: Human Error and Downtime

In traditional workflows, technicians rely on paper manuals, 2D diagrams, or verbal instructions. This often leads to:

- Misinterpretation of steps

- Improper tool usage

- Missing components

- Rework, scrap, and delays

Every error compounds costs—and even a single mistake can halt production.

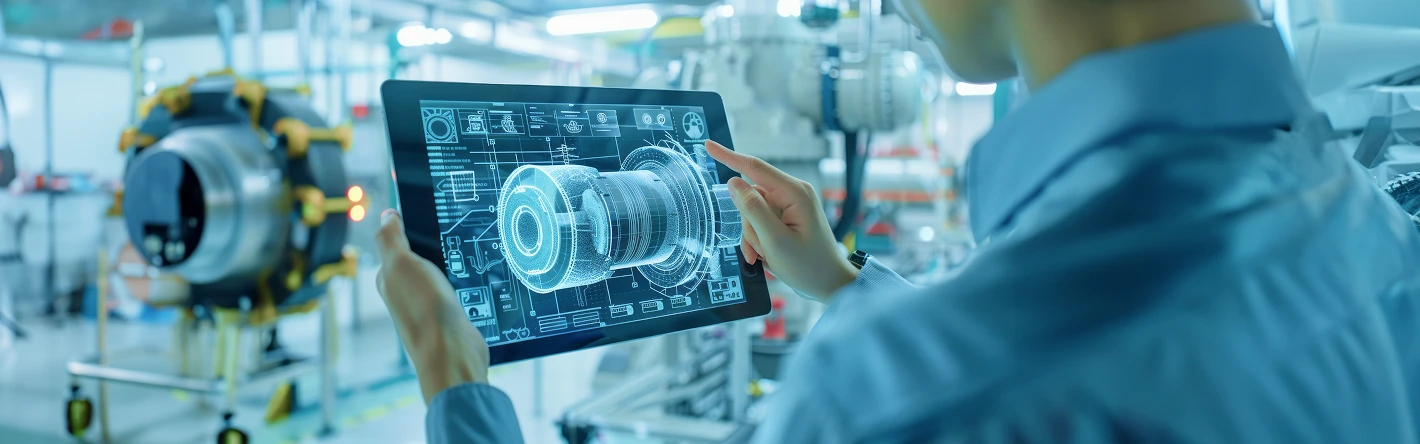

AR-Powered Connected Assembly with Fekki.io

Fekki.io’s AR manuals transform static instructions into live, interactive guidance. Technicians use smartphones or tablets to view animations overlaid directly onto the physical product, showing exactly what to do, when, and where.

Key Benefits for Assembly Teams:

Real-Time Guidance: Interactive AR steps guide technicians with pinpoint accuracy—no guessing, no flipping pages.

First-Time Right Assembly: Visual validation ensures components are installed in the correct order and orientation.

Error Prevention: Highlighting tools, parts, and procedures eliminates common assembly mistakes.

Reduced Downtime: Less rework, fewer stoppages, and faster troubleshooting when issues do arise.

Seamless Integration: AR manuals work across existing mobile devices with no special hardware needed.

A Real-World Impact Example

A leading automotive component supplier implemented Fekki.io for its wiring harness assembly process. In just 60 days, they recorded:

- 45% reduction in first-time assembly errors

- 30% improvement in throughput

- 50% drop in rework and quality control escalations

Technicians reported higher confidence and significantly less dependency on supervisors.

Closing the Loop: Data + Human Precision

Fekki.io enables true Connected Assembly by combining AR-guided workflows with analytics:

- Track common errors or hesitations

- Identify process bottlenecks

- Refine training and documentation based on real usage data

This feedback loop turns every assembly into a learning opportunity—continuously improving quality and productivity.

Conclusion

In an era of complex products and lean manufacturing, achieving first-time accuracy is critical. Fekki.io empowers technicians with the visual clarity and contextual intelligence they need to perform flawlessly. The result? A connected, efficient, and error-resistant assembly line.

Want to learn how Connected Assembly with AR can supercharge your operations? Request a demo and see Fekki.io in action.

#ConnectedAssembly #FekkiIO #ARInManufacturing #FirstTimeAccuracy #ProductivityBoost #ARManuals #SmartFactory #Industry40 #AssemblyOptimization